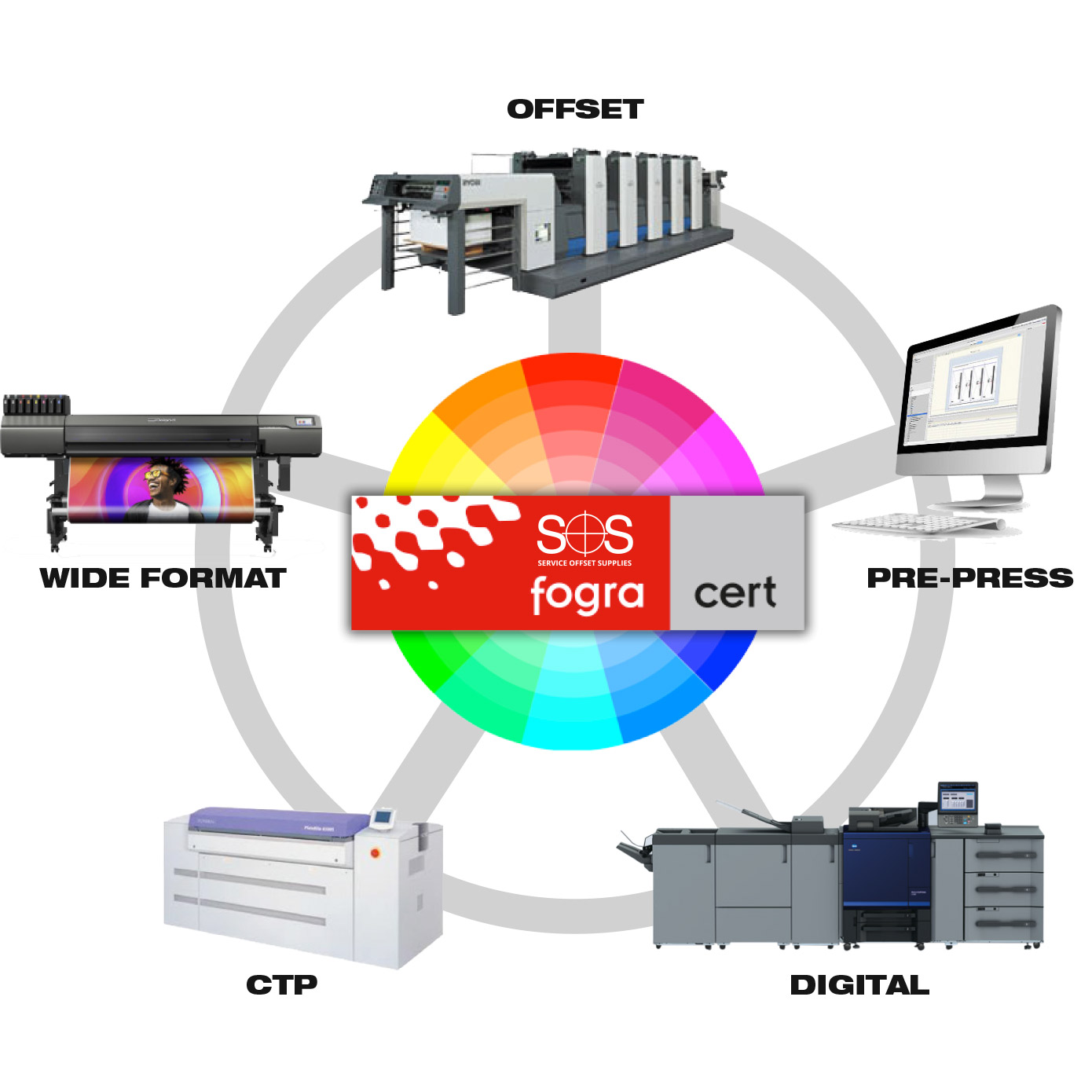

SOS Ltd are official Fogra Partners. We specialise in colour auditing and can provide full Fogra accreditation

These days, the average printer runs digital, proofing and wide format alongside litho. Achieving consistent colour across these machines can be a headache, but customers expect their poster colour to match the flyer and the brochure, and they also expect the output to match what is on the designer’s screen.

SOS is qualified to issue FOGRA certification, a measure of print quality which is a valuable yet relatively underused accreditation. Printers will often display their ISO certificate, or perhaps something to say how green they are – but rarely offer credentials which prove they are good at printing.

Here we offer some insight into a typical colour audit:

In the pre-press department, we look at how files are processed. Often, we find the ICC profiles are set incorrectly. For instance, Photoshop defaults to US standards which need to be reset. From there we need to make sure the correct profiles are delivered to each point in the workflow.

No two print companies are the same – differences in equipment and consumables are major factors, as are work profile and budget – but we are yet to encounter a printer with no room for improvement. Wide format machines and proofers often need some adjustment to hit the desired profile, despite high levels of automation and good RIP systems. Printers are often surprised by how much difference we can make.

Plate systems and litho presses often need the most attention. We calibrate the plate system to the plates, and then we spend some time on the press to get dot gain within tolerances. Litho machines are inherently quirky with many mechanical and chemical variables built-in. We determine what the deficiencies are on the press, before going back to the pre-press workflow to compensate.

Ink is a major factor. The pigments in each ink are different, and there are other chemical characteristics which are more important than density. No two inks are the same.

One of the things FOGRA researchers found was that it matters which order you put the colours down. You should always print the cyan first. Most are aware of this, but we sometimes encounter printers who are not.

Another common error is lighting conditions. Litho press consoles are supplied with specialist bulbs producing D50 daylight, but it is surprisingly common for printers to use cheap replacements which produce incorrect light. Colour perception can shift, especially at the red end of the spectrum.

We have yet to encounter a printer with no room for improvement.

Efficient colour management can also lead to cost savings. There’s an obvious benefit to producing work which is right first time, every time – less downtime, fewer reprints – but a colour audit can also reduce ink consumption. For printers with the budget to go the extra mile, SOS has a software product from Alwan which automates smart inking processes such as under-colour removal.

The biggest saving with SOS is in ongoing costs – there aren’t any. One of our key philosophies is we don’t want customers to rely on us. We educate them so they can manage and calibrate their system themselves. Some of our rivals offer maintenance contracts and tell them they need ongoing service. We don’t do that!